What is Sustainability?

Being sustainable means that development meets the needs of the present without compromising the ability of future generations.

A large focus of Turner’s outlook is decreasing the overall amount of waste that is produced and looking to reallocate that waste into other processes throughout the dairy.

The goal is a large one: to be as close to net zero (consuming only as much energy as produced) as possible. Being sustainable is an incremental process. We know that there is much more work to do but are proud of the steps we have taken to come this far. We only hope to continue to progress our efforts.

Cyclical Farming

Being intentional about farming practices is paramount to truly achieving sustainability. Sometimes referred to as cyclical farming or as regenerative agriculture, the goal is the same—to responsibly farm the land in a way that may even improve it. Cyclical farming aims to achieve a balance between the carbon emitted into the atmosphere and the carbon removed from it. The practice focuses on four key principles:

Cyclical Farm in Practice- Brookside Dairy

Operated by brothers Keith and Kevin George, Brookside Dairy has continued to make their farm more sustainable over the years with various initiatives.

In 2014, they were one of five farms in the state of Pennsylvania to receive the Clean Water Farm Award for their efforts to protect the state’s water quality. By installing streambank fencing, the dairy was able to reduce the amount of disturbance to waterways that pass through their farmland. Fencing creates a physical barrier that cattle are unable to cross. Over time, constant traffic on the water bank prevents vegetation from growing. Vegetation serves as a layer of protection from soil erosion, making the bank more stable and less likely to allow large amounts of sediment into the waterway. By stabilizing their banks, Brookside Dairy can maintain good quality water on their property while also positively affecting other properties downstream.

The shining star of the farm is its manure digester, which has been an integral part of the farm’s operations since 2006. With a herd of 400 cattle, the George’s had to be creative to deal with the animal waste being produced daily.

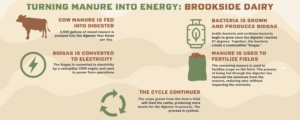

Manure is collected for the digester to process by scrapers installed in the free stall/milk cow barn and dry cow/milking parlor. The scrapers are on a timer and operate 24 hours a day. 2,500 gallons of mixed manure is pumped into the digester four times per day. Acidic bacteria and methane bacteria begin to grow once the digester reaches 97 degrees. Together, the bacteria create a combustible “biogas.” The biogas is converted to electricity by a caterpillar 3306 engine and used to power farm operations. The processed manure is used to fertilize crops on the farm.

Being fed through the digester has removed the ammonia from the manure, reducing odor without impacting the nutrients of the fertilizer. The digester has also increased the pH of the manure to 8, which is better for overall soil health. The crops grown from the farm’s field will feed the cattle, producing more waste for the digester to process. The cycle is recurrent.

Turner’s is proud to have Brookside Dairy as one of its local family farms! Click here to see how we are recycling materials to reduce our impact on the planet!